PERISTALTIC PUMPS SERIES IP Y M300

INNOVATIVE TECHNNOLOGY WITH TRADITION

For over 15 Peristaltic Pumps in form of mobile and stationary units have established themselves in the positive displacement pump market as indispensable products for industry.

For over 15 Peristaltic Pumps in form of mobile and stationary units have established themselves in the positive displacement pump market as indispensable products for industry.

Day in and day out these pumps demostrate their reliability and efficiency under the most demanding operational conditions.

Over decades the range of peristaltic pumps has been completed by intensive research, development and the use of new materials. The product range include the widest material selection for pumping hoses offered by any manufacture of these products.

The latest production methods, inspection and testing systems for quality assurance and documented production sequences in compliance with DIN EN ISO 9001 are the basis for constantly outstanding quality or the peristaltic pumps.

With the wide product range these pumps are able to meet most customer requirements, even in extremely difficult pumping processes.

Traditional values in combination with long experience and tha available pump/application know-how enables customer and market specific solution in agreed timescales.

By using the latest technologies, modern manufacturing methods and reliable service the range of Peristaltic Pumps will continue to mantain its first class position with the users in the future.

BENEFITS AT A GLANCE

• Ideal for abrasive, viscose and shear sensitive media.

• Gentle pumping of liquid or viscous products.

• Constant volume capacity due ti vacuum support.

• Dry running resistant.

• Integrated early warning system.

• Pumping of media with entrained solids.

• Unobstructed fluid flow - easy cleaning.

• Free of dynamics and pressure loaded seals.

• Portable units Series M300.

• Infinite regulations od capacity.

• High pumping pressures of max. 13 bar for Series IP.

• Dry self-priming un to max. 9.5 m lift.

• Easy operation and servicing. Only one wear item.

• Also suitable for explosive enviroment (Ex-version)

|

POSIBLE INSTALLATIONS

Our peristaltic pumps with accessories can be used for many applications and are not restricted to a specific installation location. Fixed installation directly into the process flow is possible, as is the use as mobile or portable unit that can be transported to different applications. The standard version of the pump set-up is the combination: ports on left-hand side (suction side top - pressure side bottom, red).

Of course, the IP series peristaltic pumps may be adapted to existing installations by modification of the port configuration. This only requires the relocation of the stainless steel pipe connections on the suction and discharge side of the vacuum system to suit the desired condition. This can be done without additional machining.

|

OPERATION OF SERIES IP

|

A - The rotor rotates within the pump housing filled with lubricant and compresses the pumping hose with the sliding shoe (1). This process generates a hermetic separation between suction and discharge side. |

|

B - Once the second sliding shoe (2) compresses the hose, a completely enclosed pumping chamber is formed. This volume corresponds exactly to half the pump capacity per rotation. A vacuum is also generated inside the pump housing, supporting the elasticity of the hose allowing restoration to its original full cross-section. |

|

C - The rotation of the rotor forces the pumped medium inside the hose towards the outlet port on the discharge side. During each opening of the hose a vacuum is created on the suction side ensuring constant suction. It also takes place when the hose is empty giving high suction conditions. |

|

D - With each rotation the pumping chamber is |

FLEXIBLE, MODULAR SYSTEM

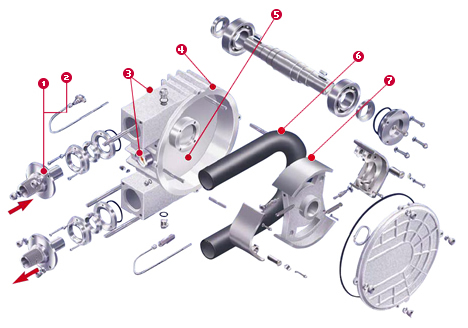

PERISTALTIC PUMP SERIES IP

|

1. Material

Stainless steel BSP / Stainless steel NPT / Stainless steel RJT / Polypropylene BSP

Polypropylene NPT / PVDF BSP / PVDF NPT

2. Ports on suction and discharge side, male thread

Suction side left-hand top (standard) / Suction side left-hand bottom

Suction side right-hand top / Suction side right-hand bottom

3. Early warning system

Vacuum switch / Conductivity measurement

4. Paint finish / Pump housing

Silver (standard) / Acid proof paint / Customer-specific according to RAL

5. Lubricant filling

Silicon oil / Glycerine

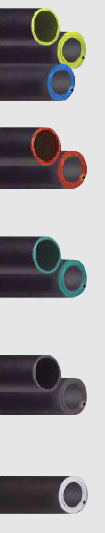

6. Hose materials

Natural rubber (NR) technical / Natural rubber (NF) food grade / Nitrile (NBR) technical

Nitrile (NBR/E) electrically conductive / Hypalone (CSM) / Butyl (IIR) / EPDM (EPDM)

Natural rubber (full fabric)

7. Pressure ratings / rotor

0 - 2 bar

2 - 4 bar

4 - 6 bar

6 - 8 bar

8 - 10 bar

10 - 13 bar

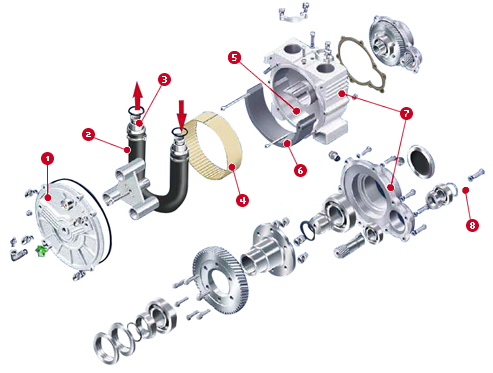

PERISTALTIC PUMP SERIES M300

|

1. Pump cover

For suction side right-hand (standard) / For reversible operation (option)

2. Hose material

Natural rubber (NR) / Nitrile (NBR) / Butyl (IIR) / Polyurethane (PUR)

Hypalon (CSM) electr. conductive

3. Camlock connections

Aluminum / Polypropylene / Stainless steel / Bronze

4.Separator

PUR

5.Lubricant filling

Silicon oil / Glycerine

6. Support

CR

7. Paint finish pump housing

Silver (standard) / Acid-proof paint / Customer specific according to RAL

8. Available drives

Electric motor 400 V AC

Electric motor 230 V AC

Electric motor Ex-version

Petrol engine

Diesel engine

Hydraulic motor

Pneumatic motor

Water turbine

OPERATION OF SERIES M 300

|

A - The rotor turns inside the tightly fixed separator. Which is held in the pump housing filled with lubricant. The separator divides the housing into two completely enclosed areas. |

|

B - Air from the suction side is pumped over the separator by the turning of the rotor and exhausted outside the pump. This forms a vacuum inside the pump chamber relative to the suction lift, which supports the elasticity of the hose during restoration to its original full cross-section. |

|

C - Once the second sliding shoe compresses the hose, a pumping chamber is formed. This volume corresponds exactly to one-third of the pump capacity per rotation. The rotation of the rotor presses the medium inside the hose towards the outlet on the discharge side. During each opening of the hose a vacuum is created on the suction side ensuring constant suction. It also takes place when the hose is empty giving high suction lift conditions. |

|

D - With each rotation the pumping chamber is reformed and the suction capability is renewed. |

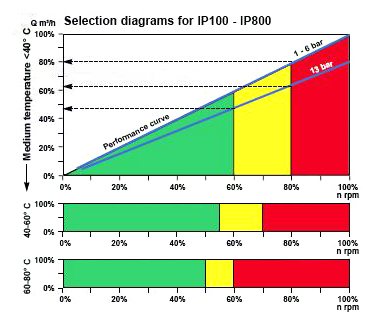

SELECTION, PUMP CAPACITY

For the selection of the mobile ELRO

Peristaltic pumps series M300, the following factors are to be considered:

• pumping medium

• pumping capacity

• suction and discharge conditions

• operation time per day

• location of use

• accessories with suitable couplings

|

The essential items for a low-wear operation of the peristaltic pumps are dependant on:

pumping media <=> speed

media temp. <=> hose compression

discharge pressure <=> Consider larger diameter discharge lines

operation time per day <=> continuous intermittent short time

|

After fixing the operation point, depending on the above parameters, an exact specification of the pump can be made using the individual data sheets. Using the selection diagram, adjustments may be necessary after consideration of the factors "Operation time/day and media temperature".

At a media temperature >40ºC, hose life is shortened and a speed reduction should be considered.

|

• Short-time operation (max. 4 hours)

• Intermittent operation (max. 12 hours)

• Continuous operation (24 hours)

ELASTOMERS

|

Natural rubber (NR) technical and approved for food applications to FDA |

|

|

For further details see our separate compatability guide.

For special applications, special full fabric hoses are available for the series IP.

Peristaltic pumps can be equipped with a suitable pumping hose for almost any application.

The great variety of different hose materials results from intensive research and long-term tests.

All pumping hoses are precision ground after the production process. This additional process ensures an uniform surface and a constant outside diameter compared with conventional hoses.

It prolongs hose life and in addition, a consistent pump capacity is achieved for all pumps.

HOUSING MATERIAL

The pump housings of the ELRO peristaltic pumps are cast from aluminium. This process which is more complicated than steel casting or welded designs is used for the following reasons:

• better heat dissipation

• integration of cooling ribs

• air tight housing

• reduction of wall thickness

• compact construction

• wear resistant

• low weight

PERISTALTIC PUMPS

SERIES IP

|

The IP series of ELRO peristaltic pumps distinguish themselves through a gentle transport of liquid or viscous media. Also capable of handling abrasive, shear-sensitive products with long fibres and solids.

Over the years they have become an integral part in the pump pool of many operators. The 13 bar pump pressures of the standard versions make ELRO peristaltic pumps suitable for replacing other pump technologies. The seven pump sizes, various hose materials including food approved versions and the different port options allow individual adaptation to each application. This variety is further expanded by the frame and motor variants.

Peristaltic pumps are equipped as a standard with a patented vacuum system. It leads to many economic and technical advantages such as:

• very good suction properties up to 9.5 m lift (no additional suction equipment required)

• constant pump capacity during the entire hose life

• enables the hose to reform to its full cross section

• low reduction in capacity when handling very

viscous media

• use as early warning system for a just in time

hose exchange

Type |

Pump Capacity

|

Inner hose diameter

|

Max. speed

|

Drive output min-max

|

Weight without drive

|

IP 100 ( 1") |

0,07 |

15 |

142 |

0,37 -1,1 |

12 |

IP 200 (1 1/4") |

0,22 |

30 |

142 |

0,55 - 1,5 |

16 |

IP 300 (1 1/2") |

0,85 |

35 |

70 |

1,1 - 4,0 |

48 |

IP 400 (2") |

1,65 |

50 |

60 |

1,5 - 5,5 |

51 |

IP 500 (2") |

2,9 |

52 |

60 |

2,2 -,7,5 |

110 |

IP 600 (2 1/2") |

4,45 |

60 |

60 |

3,0 - 11 |

123 |

IP 800 (3") |

7,8 |

70 |

60 |

5,5 - 18,5 |

148 |

|

|

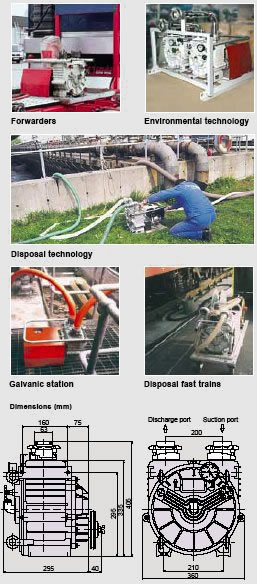

APPLICATIONS

Main application: The patented early warning system (see illustration right 2, 3) works as follows: Each hose is provided with a small additional channel through which the air in the upper section of the pumping chamber is evaquated from the pump housing. Therefore, a vacuum is formed in the sealed aluminium housing. In the case of damage or normal wear of the hose, the vacuum will drop. |

|

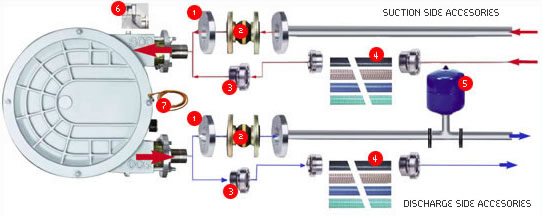

SERIES IP

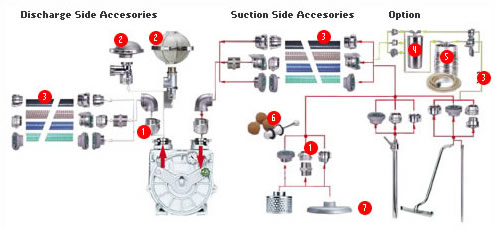

The IP series of ELRO peristaltic pumps are available with a variety of accessories for each application.

1. Flanges in steel, stainless steel and plastic according to different standards

2. Compensators in steel, stainless steel with matched elastomer materials

3. Quick action couplings and fittings, e.g. coupling in stainless steel, brass and aluminium, DIN and triclamps

4. Suction/discharge hoses are available with nominal sizes between 1? and 4? and equipped with suitable coupling systems, completely pressure-tested. Standard spiral hoses with plastic and steel reinforcement, chemical hoses or suction/discharge hoses approved for food applications.

5. Pulsation dampers made of different housing materials: lacquered steel, polypropylene or stainless steel. Depending on the type of design and size with an inner membrane complete with fittings and pressure gauge.

6. Vacuum switch for checking the vacuum in the pump housing. Pressure drop = Alarm.

7. Conductivity sensors for the conductivity measurement.

If conductivity fluid is mixed with the medium = Alarm.

|

Type |

Size |

Connections |

Hose/lubricant |

Pump pressure |

Connection position with regard to suction side viewed from front |

Base frame |

l |

10 IP100 20 IP200 30 IP300 40 IP400 50 IP500 60 IP600 80 IP800 |

E Stainless steel NPT R Stainless steel RJT S Stainless steel BSP K Polypropylene BSP T Polypropylene NPT |

A NBR electric conductive + silicon B NBR + silicon C CSM + silicon D NBR + glycerine E EPDM + silicon F EPDM + glycerine G NR + glycerine H CSM + silicon J IIR + silicon K IIR + silicon N NR + silicon W NR full fabric + silicon Y NR full fabric + glycerine |

A 0 - 2 bar B 2 - 4 bar C 4 - 6 bar D 6 - 8 bar E 8 -10 bar F 10 -13 bar |

- left/top (standard) A left/bottom B right/top C right/bottom D top/left E top/right X left/full fabric coating Y right/full fabric coating Z top/full fabric coating |

A steel painted (150-180) B steel painted (110-140) C Stainless steel D Steel painted movable E Stainless steel movable F Stainless steel specified G Stainless steel painted H steel painted (150-180) J steel painted (SF350) |

SERIES M300

|

M300 series Peristaltic Pumps were designed for safe, quick and mobile applications in the most varied industrial operating conditions. Over many years this unique, patented pump system has been and is successfully used world-wide for more and more new applications.

The basic idea during the development of the mobile peristaltic pumps was to integrate the advantages of standard peristaltic pumps and to achieve a compact, portable and flexible design. This idea was realised through a special, patented concept in the pump housing design.

Type/drive |

Weight |

M 5 E(X) ? M 20 E(X) Electric motor 230 - 400 V + EX M 15 / 7,5 E(X) ? M 20 / 10 E(X) Two-stage electric motor 400 V +EX |

55-65 kg 62-65 kg |

M 20 B Petrol engine 4,0 kW / 4000 rpm |

52 kg |

M 20 D Diesel engine 4,15 kW / 3600 rpm |

75 kg |

M 20 H Hydraulic drive M 20 L Pneumatic motor M 20 WT Water turbine M 20 FU Electric motor with integrated frequency converter |

55 kg |

Main Application: • Environmental technology The peristaltic pumps can be equipped with different hose materials depending on applications as well as with couplings on the suction and discharge side in different materials and designs. The M300 series can be selected with a variety of different motors. For special applications, the pump is also available in a reversible design. Therefore it is possible to pump in the opposite direction with the same performance features - a decisive criterion when pumping out and pumping over media which are harmful to the environment. The design of all pumps enables changing of pumping hose and all components within shortest period of time without any additional special tools. |

|

Peristaltic Pumps

Series M300

Peristaltic Pumps are available with a variety of accessories suitable for each specific application. |

Standard spiral hoses with plastic and steel reinforcement, hoses for chemical applications as well as suction/ discharge hoses approved for the food industry. |

|

Type |

Connections |

Hose/lubricant |

Base Frame |

Motor type |

Motor |

| 05 5m3/h 07 7m3/h 10 10m3/h 11 10/5m3/h 15 15m3/h 17 15/7m3/h 20 20m3/h 21 20/10m3/h OM Without Motor |

A Aluminium K Polypropylene R Brass S Stainless steel |

B NBR+silicon C CSM + silicon D NBR + glycerine G NR + glycerine H CSM + glycerine J IIR + silicon K IIR + glycerine N NR + silicon P PUR + silicon R PUR + glycerine |

E Fire brigade carrying frame stainless steel F Fire brigade carrying frame galvanised steel T Aluminium (Standard) M Vehicle stainless steel |

B Petrol D Diesel E Electric H hydraulic L Pneumatic motor W Water turbine |

- without D EEx d T4 E EEx e T3 F Faryman H Honda R Reversible Y Yanmar Z Hatz |

| Up |