NWXA PUMPS

General

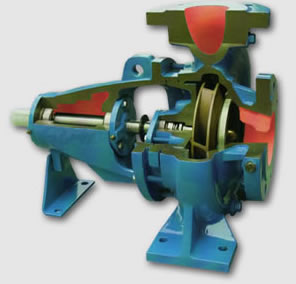

Single stage end suction centrifugal pump with foot mounted, is designed to comply with international standard EN733 which substitutes for DIN24255.

The NWXA range consists of 42 sizes, therefore the wide hydraulic coverage is further extended. Its excellent performance actually exceeds the specifications nominated by the EN733 and former DIN24255 standards.

Complete back-pull-out feature of NWXA pump allows the suction and discharge pipeline to be remained undisturbed, while the complete rotating unit is removed. This advantage enables fast and easy dismantling for servicing, resulting in lower maintenance costs.

Applications

As world-class standardized end suction pump and with widely proven quality, NWXA pump offer reliable performance for comprehensive applications such as:

• Water supply and water distribution

• Water treatment

• Fire fighting

• Pressure boosting

• General industry and process

• Circulation and water transfer in HVAC

• Drinking water

• Irrigation & Agriculture

Operating Conditions

Operating Conditions

• Pumped liquid: clean water and aggressive liquid not containing abrasive or solid particles

• Capacity: Up to 1080 m3/h

• Total head: Up to 155 m

• Discharge flanges: 32 mm to 250 mm

• Working pressure: 10 bar in standard

• Speed: Max. 3500 rpm

• Liquid temperature: up to 105ºC

• Connections: Flange and drilling to ISO 7005 PN 16

• Direction of rotation: clockwise, viewed from the drive end

Materials of construction

To meet different requirement of various applications, XA pump is available ina variety of material combinations:

Part. No. |

Description |

Material availability: S - Standard O - Optional |

||||

Grey cast iron |

Ductile iron |

Bronze LG2 |

Zinc free bronce |

316SS/1.4462 |

||

102 |

Volute casing |

S |

O |

- |

- |

O |

230 |

Impeller |

S |

- |

O |

O |

O |

210 |

Shaft |

S - SS420

|

O |

|||

161 |

Back cover |

S |

O |

- |

- |

O |

502 |

Wear ring |

S |

O |

O |

O |

O |

330 |

Bearing housing |

S

|

||||

470 |

Shaft seal |

Mechanical seal (Carbon/Ceramic) or Gland packing

|

||||

320 |

Bearing |

Deep groove ball bearing

|

||||

Design Features and Benefits

• Volute casing - Vertical top centerline discharge, self-venting. Horizontal end suction, optimum suction geometry assures outstanding NPSH performance.

• Volute casing - Vertical top centerline discharge, self-venting. Horizontal end suction, optimum suction geometry assures outstanding NPSH performance.

• Shrouded impeller - Unique hydraulics with peak efficiency 88%. Hydraulically balanced by means of balancing holes, wear rings and/or back vanes.

• Shaft - Stainless Steel is standard material.

• Back-over - Clamped or bolted between casing and bearing housing. It incorporates seal chamber.

• Replaceable wear ring - Fitted to the volute casing as standard on all sizes.

• Bearing housing - Only 4 bearing assemblies are required give thanks to modular construction design, giving high interchangeability and low spares inventory requirement.

• Shaft seal - Either sealed by DIN24960 standardized maintenance free mechanical seal or gland packing.

• Quality bearing - Each shaft module consist of two identical bearings, grease or oil lubricated, lifetime design and more reliability & less maintenance.

Performance coverage

|

Shaft Module |

|

| Up |